nano hardness tester|nanoindentation tester nht3 : distribute Nanoindentation testing is a technique used to measure a material’s mechanical properties at the nanoscale. Two key parameters obtained from nanoindentation testing are hardness and elastic modulus. Hardness, in this context, refers to a material’s resistance to plastic deformation caused by an indentation.

Find out all of the information about the J.P Selecta product: laboratory autoclave Presoclave series. Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of sale.Location of our organization is Hyderabad, Telangana. Our company has gained immense experience in the field of manufacturing of Horizontal Autoclave, Vertical Autoclave, Stainless .

{plog:ftitle_list}

You should perform autoclave chamber cleaning every 25-30 cycles to remove any residue and impurities that can build up in the bottom of the chamber from regular use. .

Nanomechanical testers from KLA Instruments ™ provide precise, reliable and repeatable measurements of hardness, Young’s modulus, and other mechanical properties to help you .The NHT³ Nanoindentation tester is designed for measuring hardness, elastic modulus, creep, and other surface properties from the nanometer to the micrometer scale. Its force ranges from .

Hit 300 is the simplest-to-use nanohardness tester on the market, featuring automated measurements, high accuracy, and a unique laser targeting system at a competitive price. . Hardness and elastic modulus of coatings can only be .

The first standard developed to address a test method for measuring “Universal Hardness” (now Martens Hardness) was DIN 50359-1 to -3 in 1997–1998 [32].It defined the test method, as well as the methods for the verification and calibration of hardness testing machines. Based on the principle above, there are many traditional methods of hardness testing, such as Vickers hardness method (Vickers), Knoop hardness method (Knoop), and Rockwell hardness method (Rockwell). . Micro/Nano mechanical testing technology and its application (in Chinese). Beijing: China Machine Press; 2005.Nanoindentation testing is a technique used to measure a material’s mechanical properties at the nanoscale. Two key parameters obtained from nanoindentation testing are hardness and elastic modulus. Hardness, in this context, refers to a material’s resistance to plastic deformation caused by an indentation.

The Nano Indenter ® G200 is used with the Express Test and the laser-heated tip and stage options for elastic modulus and indentation hardness testing of Ordinary Portland Cement (OPC) paste at temperatures from 20°C to 250°C. NanoVision was also used to generate surface topography measurements.

Vickers hardness was measured at room temperature with a Buehler Tukon model 1102 microhardness tester using a 1 kg load with 10 s dwell time to investigate its correlation with the nano hardness measurements.

Continuous Stiffness . In the original test proposed by Brinell, the load L is expressed in kilogram force. If L is measured in N (SI system), Eq. 1 should be divided by 9.8065. The full test load is applied for a period of 10–15 s. Two diameters of impression at right angles are measured (usually in the range 2–6 mm), and the mean diameter value is used for calculating the Brinell hardness .

Hardness test methods use an indenter probe that is displaced into a surface under a specific load. In traditional testing, the size or depth of indentation is measured to determine hardness leading to user bias in the data. Microhardness testing is an industry standard for quality and process control for hardness data.HVT-1000Touch Screen LCD Digital Micro Hardness Tester. Two grades micro-reading magnification with 100X and 400X times. Large LCD screen can directly show measurement methods, test force, indentation length, hardness value, dwell time of .This technology allows a user to perform Nanoindentation and Microindentation for Hardness and Elastic Modulus Testing, Stress vs Strain Analysis, Creep and Relaxation, Loss and Storage Modulus, Yield Strength and Fatigue, Fracture Toughness and Nano-scratch & Micro-scratch for Scratch Hardness Testing, Multi-pass Wear Test, Cohesive and . Nano-objects include nanoparticles, nanorods, and nanowires. Nanomechanical characterization of nano-objects is needed. . In the indentation creep test, the hardness indenter maintains its load over a period of time under well-controlled conditions, and changes in indentation size are monitored (Westbrook 1957; Mulhearn and Tabor 1960; .

nanoindentation tester nht3

→ can measure mechanical properties (e.g. modulus, hardness) on areas nm-μm scale; e.g. thin films and small volume structures → called "nano" since the indentation depth is of nanometer scale, however lateral contact areas and forces can be > nanoscale -multiaxial deformation P max a h max initial surface indenter surface profile at P max

nanoindent tester

This work presents fundamental understanding of the correlation between nanoindentation hardness and practical scratch resistance for mechanically tunable anti-reflective (AR) hardcoatings. These coatings exhibit a unique design freedom, allowing quasi-continuous variation in the thickness of a central hardcoat layer in the multilayer design, with minimal . Newey D, Wilkins MA, Pollock HM (1982) An ultra-low-load penetration hardness tester. J Phys E Sci Instrum 15:119–122. Article Google Scholar . Yang H, Shi X (2005) Comparison of nano-indentation hardness to microhardness. Surf Coat Technol 195:264–271. Article Google Scholar Ternovskij AP, Alechin VP, Shorshorov MC, Khrusshchov MM . Instrumented indentation test, also known as nanoindentation test, has been widely used to evaluate the local indentation hardness of materials at the nano- and micro-scales for academic and industrial purposes; it has been frequently compared with the Vickers hardness (HV) test used on larger scales [].A considerable number of studies have investigated the .Nanoindentation testing and scratch testing are methods to characterize material mechanical properties on micro to nano scales. Test methods include micro to nano-indentation testing for comparative and quantitative hardness and elastic modulus determination, stress and strain analysis, DMA and CSM testing and scratch testing for evaluation of wear resistance, marring, .

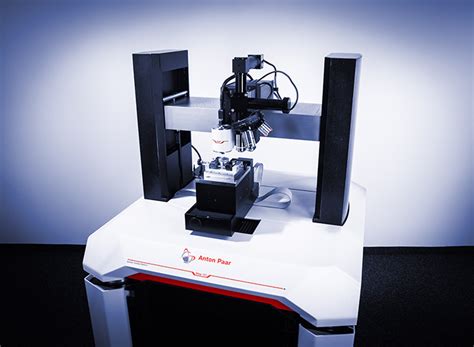

Ultra nanoindentation tester UNHT³ measures the mechanical properties of coatings and bulk materials such as hardness and elastic modulus as well as viscoelastic and creep properties from the nanoscale. . Combine the UNHT3 head with another scratch or indentation tester on the Step platform to fully cover the nano/micro/macro range. Add an .

A Nano Indenter ® G200X system was used to perform impact nanoindentation testing on aluminum, iron, stainless steel, and commercial purity magnesium. Hardness testing as a function of strain rate was compared for these materials using the ISO 14577 test method and Constant Load and Hold (CLH) testing.Nanoindentation (NI) is a nano-mechanical test that provides the mechanical properties from precise compliance measurements. In addition, nanoindentation analysis is especially useful in measuring properties such as the modulus and hardness of various shaped and sized materials.

Nano Hardness Tester. Measurement Principle: The indenter displacement is measured differentially to the sapphire reference ring, which has the advantage of negligible thermal drift errors; Head Specification: Maximum head approach range: 2 mm; Frame compliance (incl indenter): ~0.2 µm/N;

A Nano Indenter ® G200X system was used to perform impact nanoindentation testing on aluminum, iron, stainless steel, and commercial purity magnesium. Hardness testing as a function of strain rate was compared for these materials using the ISO 14577 test method and Constant Load and Hold (CLH) testing.Nanoindentation, or depth-sensing hardness testing, is a method to mechanically characterize the micro structures of materials and to analyze thin films. . a patented nano-impact test which works like a nano-mechanical charpy test, nano fretting tests for high-cycle wear tests, and more.Instrumented indentation testing, also called nanoindentation, is one of the hardness measurement methods. As an important component of material testing, it is used to determine plastic and elastic material properties such as Martens hardness HM, Indentation modulus EIT, Indentation hardness HIT and Indentation creep CIT.. In contrast to the classical hardness .

The market for "Nano Hardness Tester (NHT) Market" is examined in this report, along with the factors that are expected to drive and restrain demand over the projected period. Introduction to Nano . For decades, nanoindentation has been used for measuring mechanical properties of films with the widely used assumption that if the indentation depth does not exceed 10% of the film thickness, the substrate influence is negligible. The 10% rule was originally deduced for much thicker metallic films on steel substrates and involved only the hardness measurement. Thus, .

test for hamstring tear

„Shore A nano“, due to its unrivaled nano-test technology, enables a measurement in the entire range of the Shore-A-durometer on rubber or elastomer products. The method is based on the miniaturization of the measuring needle as defined in the standards. . Measurements of Shore A-hardness are independent of specimen sizes and geometry .

test for knee meniscus tear

anton paar nanoindent tester

In general, an autoclave is run at a temperature of 121° C for at least 30 minutes by using saturated steam under at least 15 psi of pressure. The following are the steps to be .

nano hardness tester|nanoindentation tester nht3